For the first time, manufacturing-grade cellulose has been created by using animal waste as a raw material.

If you’ve read my blogs in the past, you know I’m a fan of anything that improves circularity, and that’s just what this process does. The new technique prolongs the use cycles of materials and mitigates the environmental impact of waste disposal, researchers said.

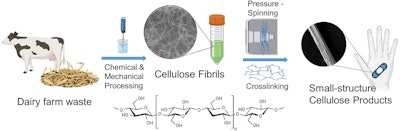

In a study published in The Journal of Cleaner Production, a new “pressurized spinning” innovation is described, showing its potential to create cellulose materials more cheaply and cleanly, using cow dung.

In a press release from University College London (UCL), researchers said implementing the new technology would “be a win-win situation for manufacturers, dairy farmers and the environment.”

Yanqi Dai, first author of the study from UCL Mechanical Engineering, said: “Dairy farm waste such as cow manure is a threat to the environment and humans, especially through waterway pollution, the release of greenhouse gases into the atmosphere when it decomposes, and the spread of pathogens. It is also often a burden on farmers to dispose of properly.”

Cellulose is one of the world’s most commonly used manufacturing materials. Found naturally in the cell walls of plants, it was first used to create synthetic materials in the mid-19th century, including the original material used in photographic film, celluloid, the press release said.

Cellulose is used in many products, including cling film, surgical masks, paper products, textiles, foods and pharmaceuticals. Though it can be extracted organically from botanical sources such as wood, plant stems and leaves, it is also often produced synthetically using toxic chemicals.

Pressurized spinning, or pressurized gyration, invented in 2013 by a team from UCL, is a manufacturing technology that uses the forces of pressure and rotation simultaneously to spin fibers, beads, ribbons, meshes and films from a liquid jet of soft matter.

“Our initial question was whether it could be possible to extract the tiny fragments of cellulose present in cow manure, which is leftover from the plants the animals have eaten, and fashion it into manufacturing-grade cellulose materials,” said Professor Mohan Edirisinghe, the senior author of the study. “Extracting the fragments from dung was relatively straightforward using mild chemical reactions and homogenization, which we then turned into a liquid solution. But when we tried to turn the fragments into fibers using pressurized spinning technology, it didn’t work.

“By a process of trial and error, we figured out that using a horizontal rather than a vertical vessel containing surface nozzles and injecting the jet of liquid into still or flowing water caused cellulose fibers to form. We were then able to change the consistency of the liquid to create other forms, such as meshes, films and ribbons, each of which have different manufacturing applications.

“We’re still not quite sure why the process works, but the important thing is that it does. It will also be fairly easy to scale up using existing pressurized spinning technology, the vessels for which were designed and built in the UCL Mechanical Engineering workshop.”

The new technique, called horizontal nozzle-pressurized spinning, is an energy-efficient process that doesn’t require the high voltages of other fiber production techniques such as electrospinning.

“Horizontal nozzle-pressurized spinning could be a huge boost to the global dairy farming industry, by putting this problematic waste product to good use and perhaps creating a new source of income,” the researchers said.

The research team is seeking opportunities to work with dairy farmers to take advantage of the technology and scale it up. Future research will focus on optimizing process efficiency and gaining deeper insights into the functional performance of the extracted cellulose to broaden its applicability, the researchers said.